Roxel is a European leader in the field of tactical propulsion. We develop, manufacture and market all types of motors for tactical and cruise weapons systems used around the world.

Roxel is renowned for its expertise in developing and optimising specialised materials to provide its customers with tailored solutions for all components of propulsion systems, including structures, thermal protection and energetic and inert materials.

The Group meets the most demanding requirements for performance, reliability and safety. We are the world leader in Insensitive Munitions (IM) technology for minimum smoke propellants.

Roxel’s motors are used across all categories of missiles and rockets: air-to-air, surface-to-air, artillery, anti-ship, anti-tank, air-to-surface, cruise missiles and guided bombs. For example, we are responsible for the propulsion systems used in the following missiles: EXOCET, ASTER, MAGIC, MICA, MILAN, ASRAAM, RBS15, CAMM, Brimstone and Akeron MP, among others. Moreover, Roxel designs and supplies pyromechanisms, gas generators and a standardised range of motors for the decoy, target and drone systems market.

In May 2008, Protac, a leading French designer and manufacturer of missile and rocket motors, joined Roxel. Protac was founded in 1994 through the merger of the propulsion activities of Thomson Brandt Armements and Bayern-Chemie.

Thanks to its history, Roxel benefits from extensive experience in the field of solid propulsion. This centuries-old legacy is forged by the unique history and expertise of each site and its workforce: Saint-Médard (since 1960), Summerfield (since 1951), Bourges (since 1965), and La Ferté (since 1938).

In December 2024, MBDA acquired the remaining 50% stake held by Safran, making Roxel a wholly-owned subsidiary. This acquisition aims to strengthen and enhance Roxel’s current and future capabilities, and comes at a time of significant growth and major investment.

Le Plessis-Robinson (near Paris) – France

Business center “La Boursidière”

92357 Le Plessis Robinson

Group headquarters, Sales & Marketing Directorate, Strategy, Communication, Legal

La Ferté Saint-Aubin (Centre, near Orléans) – France

Route d’Ardon – 45240 La Ferté-Saint-Aubin

Manufacture and control of inert materials • Industrialisation & manufacture of rocket motor cases • Flowforming (all types of metals) • Study, design and manufacture of thrust struts and other aeronautical devices • Industrialisation & manufacture of rocket motor thermal insulations • Manufacture of rocket motor thermal insulations (presses, autoclave…)

Bourges production site

Bourges (Centre) – France

1 route de l’Aérospatiale – 18570 Le Subdray

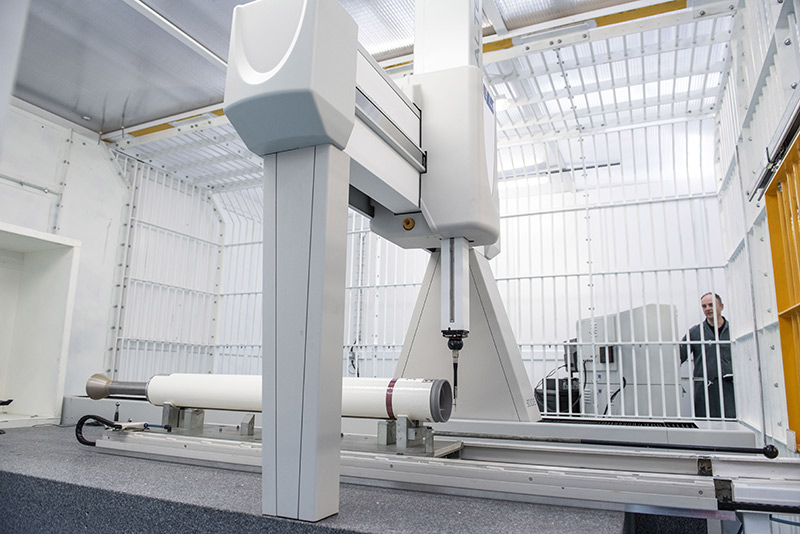

Study and design of solid rocket motors • Full integration of rocket motors • Test centre • Study, design and manufacture of igniters • Rocket motor disposal

St Médard-en-Jalles (Aquitaine, near Bordeaux) – France

BP 50058 – Avenue Gay Lussac – 33167 Saint-Médard-en-Jalles

Study and design of solid rocket motors • Manufacture and implementation of the different types of propellant (Composites, Extruded double base (EDB), solvent less) • Test centre • Integration (Rocket and drones) • Manufacture and control of liners and inhibitors • Study, design and manufacture of igniters • Rocket motor disposal

Summerfield (Worcestershire, near Birmingham) – United Kingdom

Summerfield – Kidderminster

Worcestershire DY11 7RZ

Study, design and manufacture of solid rocket motors • Full integration of rocket motors • Test centre (including Wyre Forest facility) • Manufacture and implementation of Cast double base (CDB) • Specialist capability for small EDB charges • CDB and inert material lab • SSL structure (steel strip laminate) • Study, design and manufacture of igniters

Production site

Group headquarters

Production site

Production site

Production site

The Saint-Médard-en-Jalles site is the oldest powder manufacturing facility still in operation today.

In 1660, Sir Dupérier purchased the land where the site now stands, located in the parish of Saint-Médard, on which the ruins of an old mill were located. Around these ruins, Dupérier built six mills dedicated to pyrotechnic production.

Following Dupérier’s death in an explosion in 1663, Louis XIV entrusted the land to François Berthelot, who later purchased it. In 1671, the Saint-Médard Powder Mill officially became state property.

For the next two centuries, the National Powder Mill only produced black powder (also known as gunpowder). However, the 19th century marked a turning point in the mill’s history, with the establishment of a production unit for nitrocellulose powder. This new powder, known as ‘Powder B’ (after General Boulanger), was used as a propelling charge in ammunition for the 75 mm 1897 model field gun.

The 20th century saw a major evolution in the field of propellants, particularly following the research carried out during the Second World War. This period marked the transition from traditional powders to solid propellants, ushering in a new era for the Saint-Médard site.

By the 1950s, new types of propellants had been developed, enabling far greater

performance.

Using new chemical components, these propellants enabled the propulsion of

intercontinental missiles, thereby driving further expansion at the Saint-Médard site.

The site includes 160,000 m² of buildings.

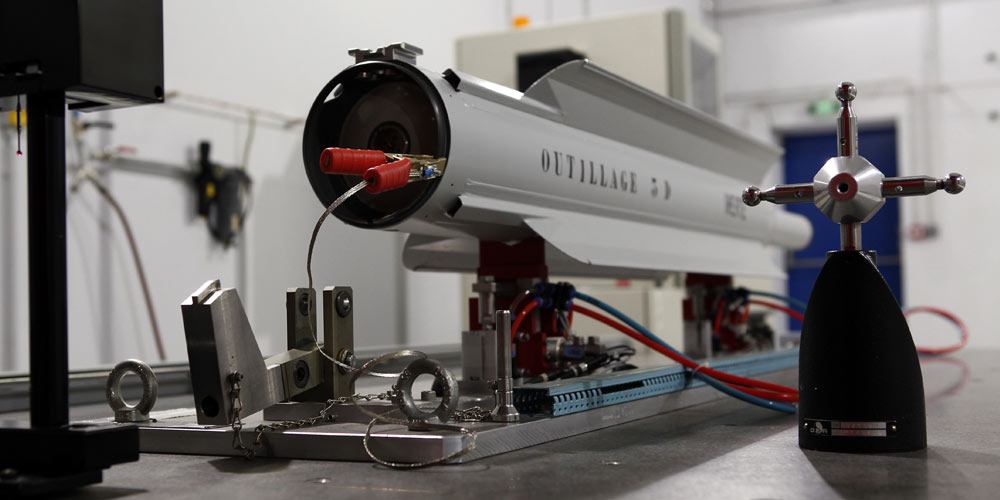

The Subdray site was established in 1963 to conduct the many static firing tests required for rocket motors. Initially, it housed static firing test benches and environmental testing facilities.

In the meantime, SNCAN became Nord-Aviation.

In 1970, SNIAS was formed through the merger of Nord-Aviation and Sud-Aviation, the latter best known for its successes with Caravelle and Concorde. SNIAS was later renamed Aérospatiale.

The Subdray site expanded alongside the launch of R&D efforts for second-generation missiles, including the rocket-propelled MILAN, HOT, ROLAND, EXOCET and AS30L, and the ramjet-powered ASMP.

In 1992, the heads of Aérospatiale and SNPE decided to merge their propulsion operations to strengthen their position in the solid propellant motor market for all types of tactical and cruise missiles, aiming to restructure this industry in France and Europe. The following year, Celerg acquired industrial production facilities in Bourges, where its flagship products were the EXOCET, ASTER and ERYX rocket motors.

Roxel was founded ten years later through the merger with the UK’s Royal Ordnance.

The origins of the site in La Ferté Saint-Aubin date back to 1936, when Edgar Brandt acquired the land for the mass production of 20 to 25 mm cartridges.

Propulsion operations began in 1955 with early research on solid propellant motors for Matra’s first missile programme, conducted at La Ferté Saint-Aubin in collaboration with Matra.

In 1994, Thomson-CSF and DASA (Deutsche Aerospace) decided to combine their armament and tactical missile propulsion operations by creating two joint ventures: TDA for armament, and Bayern-Chemie for propulsion systems, with its French subsidiary, Protac (tactical propulsion), based in La Ferté Saint-Aubin and formed from the site’s propulsion department.

The Summerfield site was created in the early 1950s in response to the UK’s need for a facility dedicated to R&D for cast double-base propellants.

The site was operated by the Metals Division of Imperial Chemical Industries (ICI) and then later renamed the Summerfield Research Station (SRS).

The capabilities of Summerfield have been expanded over the years with the addition of a static firing test range. Initially on site, in 1952, a lease was secured on 50 hectares of the Wyre Forest from the Forestry Commission, which is still in use today. Over the years, the Wyre Forest site has become one of the most advanced testing facilities available. It features the only large centrifuge capable of spin-launching missiles, numerous vibration test benches, plus various environmental testing chambers.

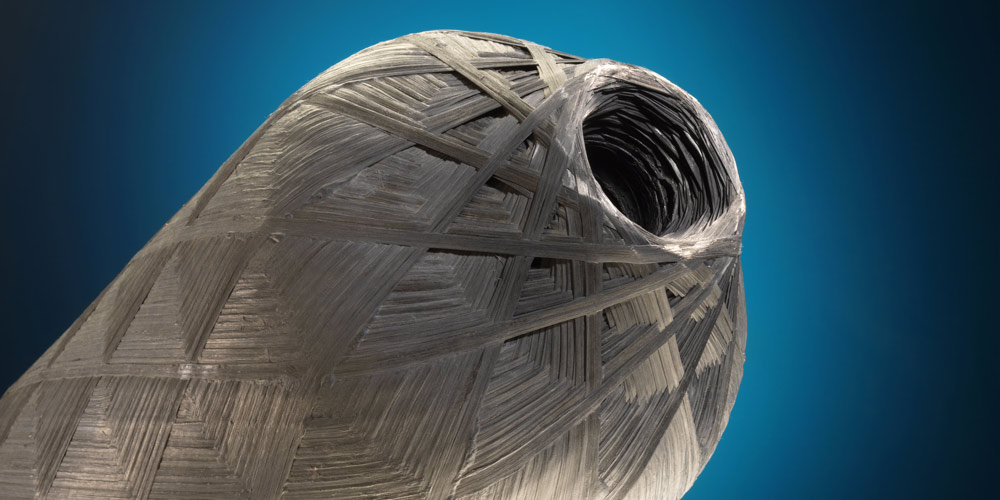

The evolution of propulsion systems has always been closely tied to advancements in propellants and their adaptation to the specific needs of various missile systems (i.e., air-to-air, anti-tank, etc.). Over time, Roxel’s chemists have developed booster and cruise propellants to meet the unique requirements of each programme.

The Summerfield site has welcomed many industry experts over the years including

Bernard Walkley, holder of the patent for the manufacture of laminated strip rocket motor casings which was a ground-breaking process at the time. This technique was first deployed in Summerfield on the Saluki motor, developed for the Blue Water nuclear missile project.

The same technology for producing strong, lightweight, insensitive motor casings was later used on the TROY surface-to-air missile and continues to be used today in a range of systems, including ASRAAM and CAMM.

Chief Executive Officer

Managing Director Roxel Summerfield

Chief Financial Officer

Marketing, Sales & Chief Programmes Officer France

Industrial Director

Chief Technology Officer

R&T and Innovation Director

Quality Director

Improvement & Digital Director

Human Resources Director

Therefore, we have voluntarily incorporated the seven core principles of the ISO 26000 standard into our business model. We are committed to:

Through these commitments, we strive to balance economic performance with social responsibility, actively contributing to a fairer and more sustainable future for our planet.

At Roxel, we recognise that our employees are our most valuable asset. Their commitment, expertise and creativity are the foundations of our success. We are committed to ensuring the highest quality of working life for our teams and making sure that they share in our success.

At Roxel, we believe inclusion is a key driver of our success.

We are committed to ensuring everyone feels welcomed, included and able to achieve their highest potential whilst working with or for Roxel. We value and respect our people and their unique abilities. We are committed to fostering local partnerships to strengthen ties and support the communities within in which we operate.

Roxel is committed to building a sustainable future. We are actively working to reduce waste, limit our use of materials and energy, shrink our carbon footprint and protect biodiversity, all with the aim of contributing to a greener, more responsible world.

To support energy performance improvements, Roxel France obtained ISO 50001 certification at the end of 2024. The goal of this international standard is to implement and continuously improve the company’s energy management system.

Roxel is committed to building high-quality relationships with its suppliers through a responsible procurement policy.

To guarantee the production of sustainable solutions, Roxel relies on a collaborative approach with its suppliers aimed at developing and strengthening synergies. Roxel’s procurement policy therefore outlines the following expectations for our suppliers:

Roxel is committed to upholding high standards of ethics, compliance and corporate social responsibility. We expect our suppliers to share this commitment, so that together we can build a more sustainable future.

To support our suppliers in this process, Roxel provides them with the company’s

Responsible Supplier principles and guidelines.

For the purposes of conducting its business, Roxel may be required to collect and process personal data.

In this regard, Roxel is committed to complying with applicable regulations and upholding the highest standards of compliance to ensure the security, lawfulness, legitimacy and fairness of data collection and processing, as well as respecting the fundamental rights and freedoms of data subjects.

Roxel is committed to ensuring neutrality and fairness in its decision-making and external stakeholder relationships, guided in particular by:

• a Code of Ethics

• an Anti-Corruption Policy

• an Export Control Policy

• a Supplier Relations and Responsible Procurement Charter

Movements of military and dual-use goods are strictly regulated at both national and international levels.

These regulations are designed to ensure that technologies meant for national and

international peacekeeping and security do not end up in the hands of sanctioned countries, entities or individuals, and that they are not integrated into prohibited systems.

In this respect, Roxel strictly complies with national and international regulations and reports on all its activities to the relevant authorities.

Roxel has adopted a proactive strategy to prevent and manage competition-related risks, establishing a compliance programme designed to prevent breaches of competition law and to raise awareness among employees.

Roxel is fully aware of the impact and the importance of its operations. As such, we have adopted a proactive approach to combat corruption and related practices. All Roxel employees and stakeholders are expected to actively combat corruption and related practices and to embody the following core values: legality, honesty, trust, performance, transparency, openness, integrity and responsibility.

These are not just words, these are the standards our company lives by. In this respect, Roxel gives all stakeholders and employees the right to report any wrongdoing, conducts risk mapping for corruption and related practices, makes every effort to ensure that stakeholders are not suspected of corruption, and sets clear rules to govern gifts and hospitality, conflicts of interest, the use of commercial agents and all charitable activities.

Political contributions and facilitation payments are strictly prohibited. All stakeholders, including commercial agents, must comply with Roxel’s standards. Failure to do so will result in immediate action.

To ensure that these standards are understood and upheld, Roxel regularly organises awareness campaigns for employees and provides relevant information to all stakeholders.