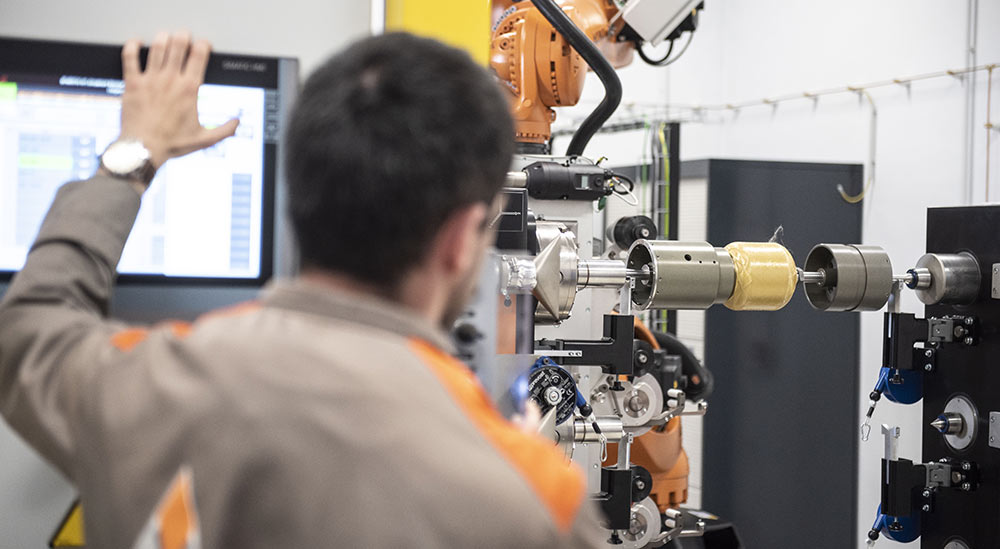

Design and development

Roxel manages the full lifecycle of its propulsion systems, from design through to dismantling and disposal. Our expertise also includes technology research, development studies, qualification, series production and in-service support.

To meet the requirements of our European and international customers, Roxel provides highly qualified project managers and dedicated teams who have all the necessary know-how and expertise.

Thanks to our thorough understanding of all propulsion system components and their interfaces, we design and develop complete rocket motors tailored to market needs and performance requirements.

Roxel’s expertise covers propulsion systems for land, naval and air-borne applications, including air-to-surface artillery rockets, tactical missiles and cruise missiles.

Leveraging this recognised expertise, Roxel provides:

• Innovative propulsion systems developed from an initial concept

• Mid-life upgrades for existing systems

• Refurbishment of existing systems

• Re-powering for existing systems

• Joint development of motors in collaboration with local designers or manufacturers

• Innovative solutions developed through R&D programmes

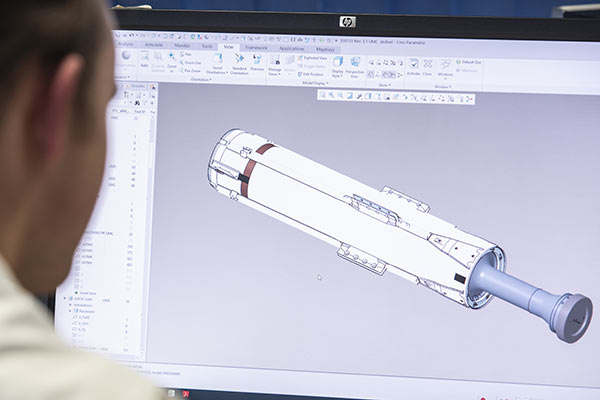

Roxel also develops skills in advanced digital tools to optimise system performance. These tools enable us to:

• Reduce the number of prototypes and qualification tests (helping to reduce environmental impact)

• Maximise the return on investment of each test by refining measurement definitions and analyses

• Provide effective support for failure analysis

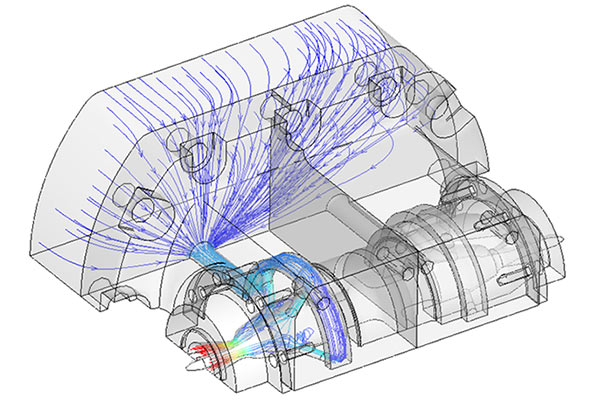

Roxel has proven experience in modelling and design engineering in the following areas:

• Ballistic analysis

• Mechanical and thermal analysis

• Computational Fluid Dynamics (CFD)

• Thermochemical analysis

• Reliability / failure analysis

• Insensitive Munitions (IMs) modelling

Production

In addition to design and development, Roxel manages large scale production of propulsion systems including structural components and energetic / inert materials. Final assembly is also undertaken.

Roxel operates four production sites, located in France (Saint-Médard, Bourges, La Ferté Saint-Aubin) and the United Kingdom (Summerfield), all adhering to the highest standards of quality and safety in the pyrotechnics field.

Integrated Propulsion Systems

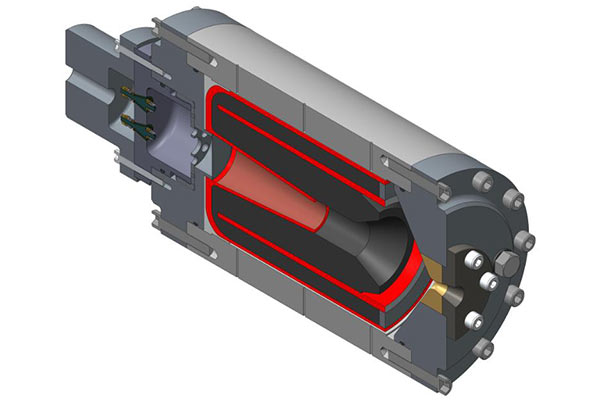

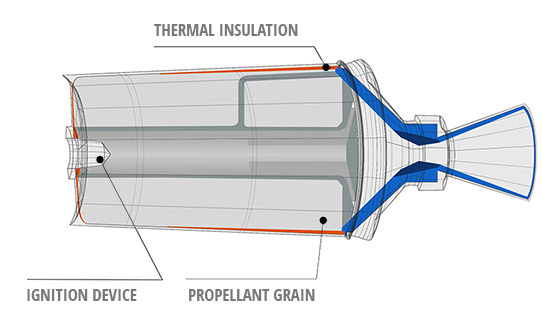

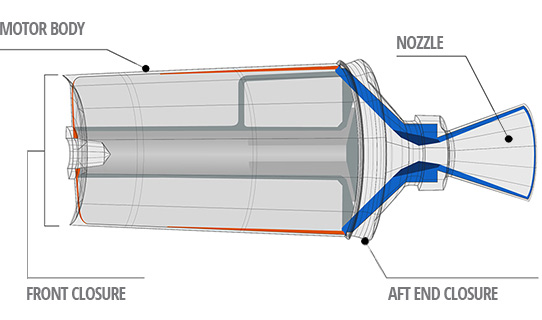

A rocket motor is mainly composed of:

• A motor casing, usually part of the rocket or missile’s external structure

• Insulation layers protecting the casing from thermal and/or chemical stress

• Propellant

• Interconnecting blast tubes and nozzles with or without jet deflection devices (flexible stops, jet deflectors, etc.)

• An ignition system

• In some cases the rocket motor also includes other components such as an Igniter Safety Device (ISD), external thermal insulation, hangers, etc.

Roxel offers one of the most comprehensive ranges of propellants, motor casings and related materials, including:

• Energetic materials: propellants (EDB, CDB, composite propellants)

• Manufacturing technologies for rocket motor structures

Energetic materials

Roxel has specialised expertise and resources to design, develop and manufacture a full range of solid propellant-based energetic materials. Solid propellant combines fuel, an oxidizer and additives to control ballistic and physical properties. It may be cast, extruded or even machined to the required shape.

Roxel can produce solid propellants of all sizes (in terms of mass and diameter) for tactical propulsion systems.

Qualified Teams

Roxel employs COFREND-COSAC level 1 and 2 (penetrant testing, ultrasonic testing, and radiography) certified personnel in France, and ASNT level 3 (radiography, ultrasonic testing, magnetic particle testing and penetrant testing) certified personnel in the UK. A dedicated supply chain team operates across all our production sites.

Composite propellants (mainly HTPB-based)

Composite propellants are mainly made of a solid oxidizer, an organic binder, metal powder and various additives to control ballistic and mechanical properties.

• Cast composite

• Extruded-curable composite

Double-base propellants

Double-base propellants are mainly made of nitrocellulose and nitro-glycerine. Additives are included to control ballistic and mechanical properties and ensure chemical stability.

• Cast Double Base (CDB)

• Cross-Linked Double Base (XLDB)

• Elastomer-Modified CDB (EMCDB)

• Extruded Double Base (EDB)

Advanced energetic propellants

Propellants based on novel materials (ADN, FOX, GAP)

Inert materials

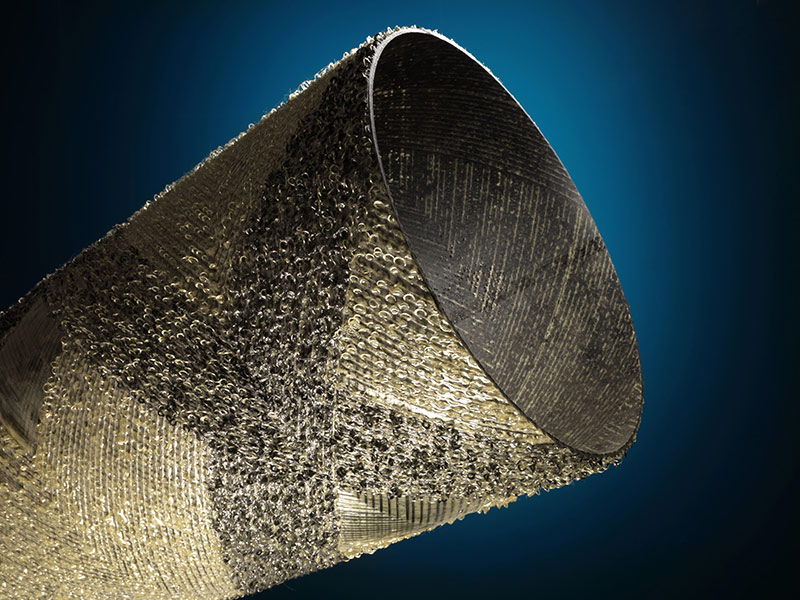

Roxel, designs, develops and manufactures a broad range of inert materials. These are used for structural protection and for inhibiting propellant grains where needed.

These inert materials must meet the following criteria:

• High thermal shock and heat resistance

• Low thermal conductivity to limit heat transfer

• Mechanical shock resistance during ignition

• Chemical and mechanical erosion resistance to combustion gases

• Chemical compatibility with both the propellant grain and combustion gases

Inert materials can be classified under the following categories:

• Elastomers, such as silicones and rubbers: used in thermal insulation, ablative protection for short-duration systems, flexible thrust nozzles, inhibitors, adhesives, etc.

• Phenolic resins used for rigid materials: provide thermal insulation for reinforcing combustion chambers, piping, heads, ramjet nozzles and casings, intumescent paints, etc.

• Ceramics and composite materials: used for thrust vector control (TVC) components such

as nozzles, valves, jet vanes, etc.

• Refractory metals, such as molybdenum: used in nozzles, jet deflectors, etc.

Structures

Through its versatile range of in-house technologies for motor casing production, Roxel is able to design and deliver optimal solutions that strike the right balance between cost, performance and IM characteristics, in line with customer requirements.

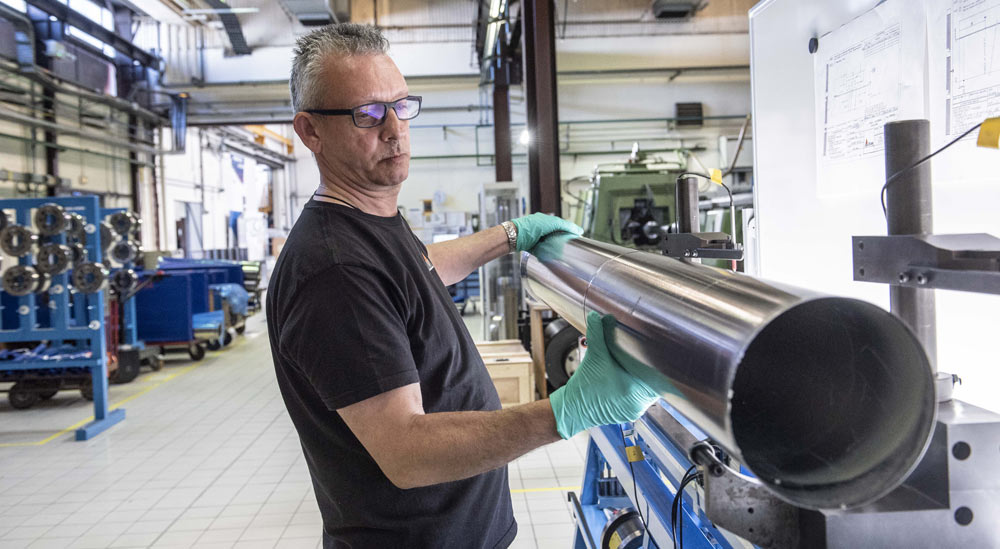

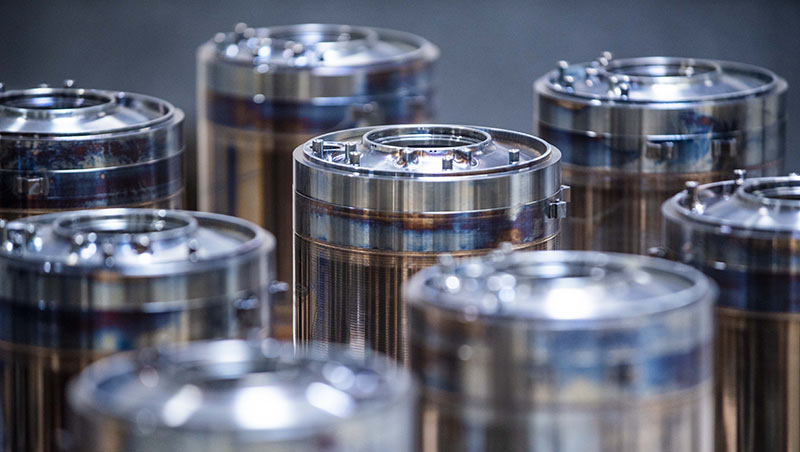

Metallic structures

Metal motor casings offer high rigidity and retain their strength even when exposed to high temperatures.

• Flow-formed structures are made by shaping a metal tube over a mandrel. Rollers apply high pressure, causing the metal to creep and form around the mandrel to achieve the desired shape and thickness. During this process, the structure is cold worked, resulting in a

higher hardness metal casing.

• Steel

• Aluminium

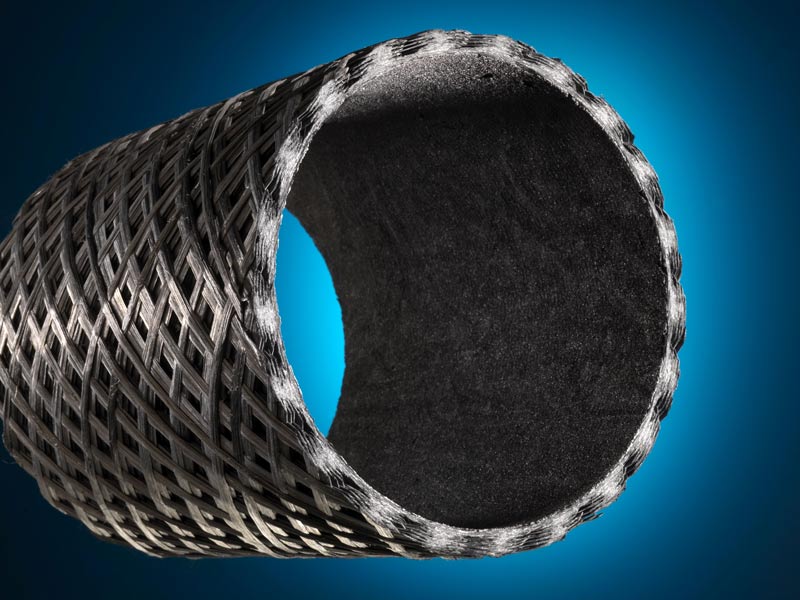

Composite structures

Composite structures are lightweight and allow for a wide range of configurations. They are especially well-suited to meet IM requirements related to fire and bullet impact.

• Kevlar

• Steel Strip Laminate (SSL)

Hybrid structures

Hybrid casings combine fibres, resins and a metallic structure. They offer a middle ground between fully metallic and fully composite casings.

• Kevlar Overwound Aluminium (KOA)

KOA casings offer high pressure resistance, reduced weight and improved IM characteristics. This technique is already in use in several operational motor casings.

Testing

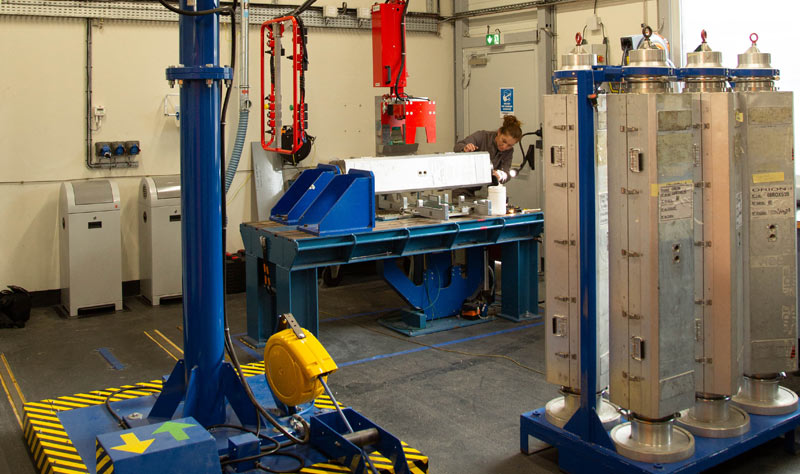

Roxel has an extensive range of testing equipment for all types of measurements and performs all development and acceptance tests for motors and other systems, both for customers and in-house needs.

More Than 20 Test Benches

• All types of motor level test benches: horizontal and vertical, including 6-axis benches

• Specialised test benches: vacuum, underwater, depth simulators, vertical and horizontal, rotating, and centrifuge benches

• Other facilities: thermal insulation testing, cold gas propulsion testing, burst pressure testing with or without mechanical stress, kerosene torch igniter testing

• Plume opacity and luminance measurement

Comprehensive Data Acquisition and Processing Systems

• Measurement of all key parameters: pressure, blast overpressure, thrust, shock, strain, temperature, etc.

• High-speed video and imaging

• Fast data acquisition modules

• Real-time X-ray control, display and imaging

• Ultrasonic and infrared thermographic measurements

Expanded Testing Capabilities

• Motors up to 4 metres in length, 600 mm in diameter, and 1,200 kg of propellant

• Pre-test operations: pyrotechnic building for integration and instrumentation, temperature conditioning, and X-ray inspection

• Post-test operations: dedicated facility for motor sectioning and analysis

• Centrifuge testing – missile levels

Integration

In addition to its expertise in core rocket motor components (i.e. energetic materials, structures and inert materials), Roxel also manages the assembly and integration processes. Roxel studies, designs and manufactures propulsion systems based on customer specifications including, thrust, weight, dimensions, and missile integration requirements.

Integration and Quality Control

The above elements and externally sourced basic components are integrated into the motors at Roxel’s facilities. During final assembly, operations such as painting and on-site quality control activities are completed.